Sample Transporters

- Exceptional Control: Experience near force-free manipulation with precise control.

- High-temperature bakeout: Suitable for bakeout temperatures up to 200°C.

- Versatile configurations: Available in standard strokes (100-500mm) with customization options up to 750mm.

What are Sample Transporters?

Ferrovac magnetically driven manipulators set the standard for precise and delicate movements within ultra-high vacuum (UHV) environments. Unlike traditional bellows-based motion feedthroughs, our magnetic coupling technology eliminates the risk of leaks and ensures exceptional longevity.

Why Choose Ferrovac Sample Transporters?

Eco-Friendly and Cost-Effective: With a maintenance-free lifespan of up to 10 years and readily available spare parts, these manipulators reduce environmental impact and long-term costs.

Precision and Reliability: Engineered for ultra-high vacuum (UHV) systems, Ferrovac Sample Transporters operate seamlessly in pressures ranging from 1E-11 to 1000 mbar.

Versatile Functionality: Multiple configurations and accessoires make the Sample Transporter adaptable for a wide range of applications far beyond transporting samples.

Typical Applications

Ferrovac Sample Transporters are available in various configurations to meet a wide range of applications, such as:

- Sample Handling: Precise transportation of samples within the vacuum chamber.

- Sample Parking: Creates compact and easy-to-use parking racks when combined with a stack of receptacles.

- Heating Stage Carrier: Ideal to carry mobile sample heating stages

- In-Vacuum Tools: Engage and disengage thermal links, activate screws, utilize scrapers, and much more.

- And much more…

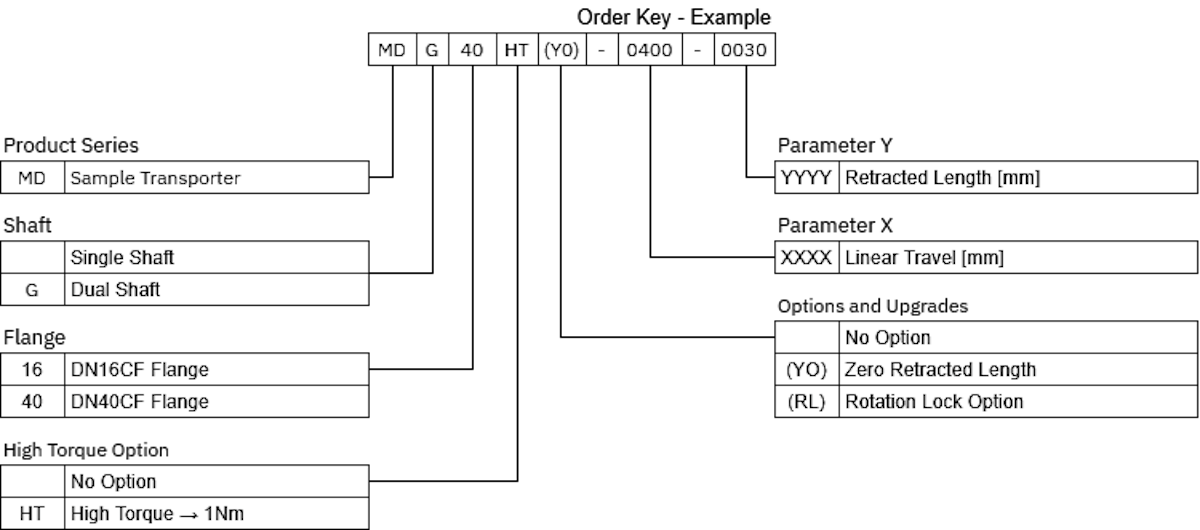

Product Code:

Viewing enlarged image:

Shaft:

For most sample transporter applications, the single shaft option fulfills all requirements.

They offer both rotational movement and linear extension/retraction, while maintaining a highly tactile feel and smooth operation.In certain cases a dual-shaft solution offers additional actuation for vacuum-side end effectors.

Flange:

Sample Transporters are available with mounting flanges in the standard sizes DN16CF and DN40CF.

Retracted Length [mm]

Specifies the minimal length of the shaft extending from the DN40CF flange surface towards the vacuum side, while the manipulator shaft is fully retracted.

Linear Travel [mm]

The maximum travel distance of the Sample Transporter shaft. Added to the retracted length, this defines the shaft's maximum extension into the vacuum chamber.

Options:

HT Option - For Heavy Load Applications: For applications that require increased force, the High Torque version delivers more power for tasks such as securely fastening sample holders in position, or engaging a mechanically activated thermal link. It ensures the reliable application of high torque without compromising precision

(Y0) Option - Zero Retracted Length Option: Designed to make the most out of the space available in our UHV suitcase chambers, this version sports the shortest possible retracted shaft length on the vacuum side.

(RL) Option - For Controlled Rotation Limits: In some applications where visibility is low, or in cases where very fragile components are handled, the limitless, continuous rotation capabilities of the sample transporter can be limited with an optional Rotation Limit component.

Sample Transporter (DN16CF)

MD16-XXXX-YYYY

From1’800.00 CHF

Sample Transporter (DN40CF)

MD40-XXXX-YYYY

From2’000.00 CHF

High-Torque Sample Transporter (DN40CF)

MD40HT-XXXX-YYYY

From3’900.00 CHF

Dual-Shaft Sample Transporter (DN40CF)

MDG40-XXXX-YYYY

From5’000.00 CHF

Sample Transporter (DN40CF), Zero Retracted Length

MD40(Y0)-XXXX-0001

From2’500.00 CHF

Factory Overhaul Sample Transporter

SERFMD16 / SERFMD40

From790.00 CHF