Heavy-Duty Sample Transporters

- Exceptional Control: Experience near force-free manipulation with precise control.

- High-temperature bakeout: Suitable for bakeout temperatures up to 200°C.

- Extended Reach: Available for transfer distances up to 1250mm, perfect for large UHV systems.

What are Heavy-Duty Sample Transporters?

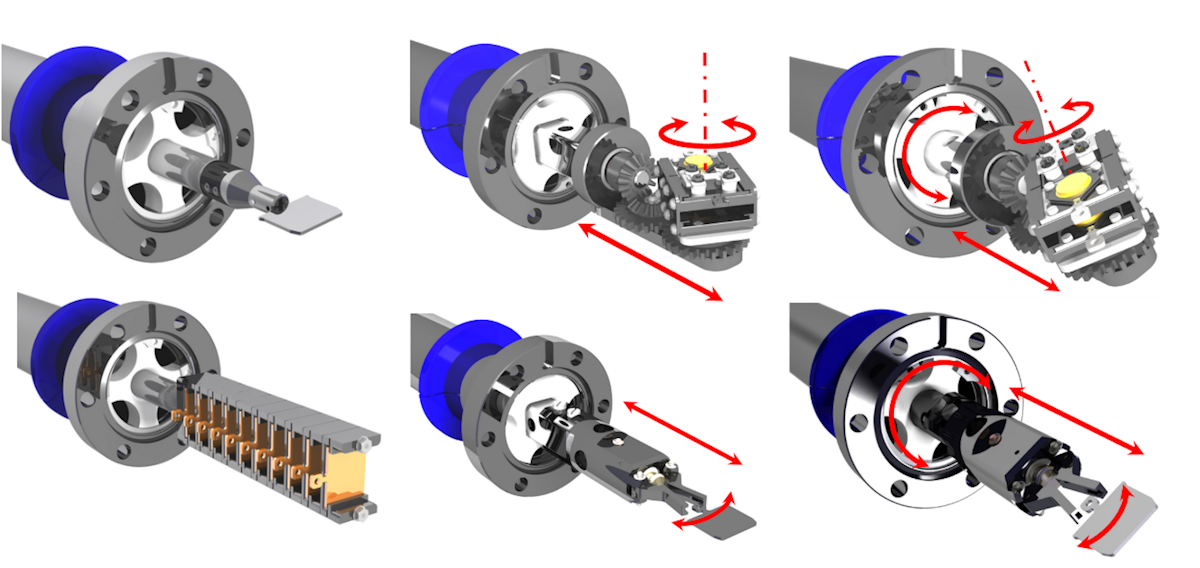

This heavy-duty version of our magnetically driven sample transporters is built for your most challenging transfer needs. Featuring reinforced construction and high-strength magnets, it offers unmatched robustness and reliability for transferring samples between multi-chamber UHV systems, over long distances, or with heavier payloads. Ideal for transferring samples over extended distances in vacuum, navigating complex chamber setups, or transferring large samples.

Typical Applications

Ferrovac Sample Transporters are available in various configurations to meet a wide range of applications, such as:

- Long Range Handling: Low deflection transportation of samples over longer distances is made possible with the use of a rigid, square shaft and precision engineered bearings.

- Automated Exchange: Ideal in combination with various motorization upgrades for a fully automated sample handling system.

- Heavy Load Carrier: High coupling forces enable the transport and manipulation of heavy loads, large sample racks or other heavy-duty applications.

- And much more…

Viewing enlarged image:

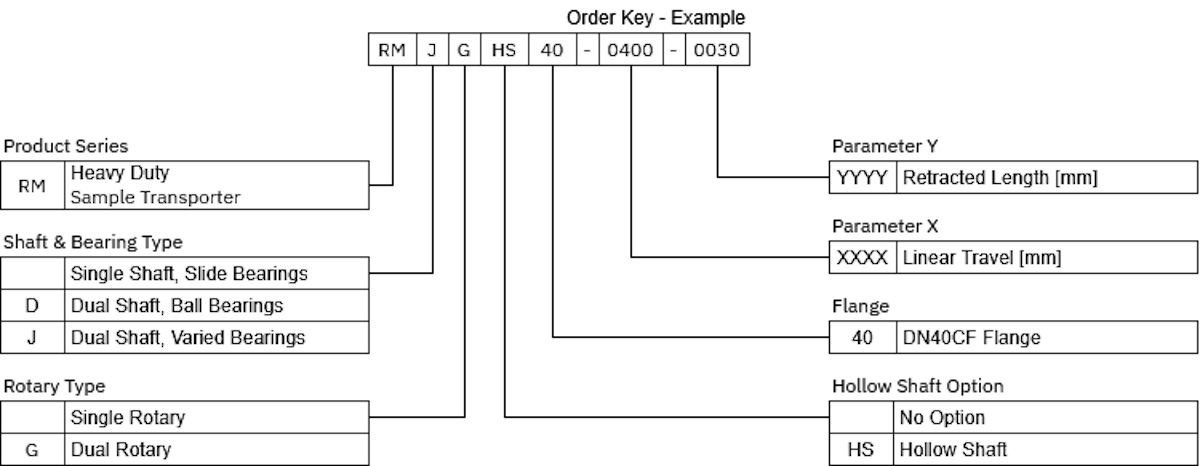

Shaft & Bearing Type:

Heavy-Duty Sample Transporters are outfitted with precision engineered slide bearings that are optimized for long distance travel ranges and UHV environments.

The inner shaft of dual-shaft manipulators makes use of high-precision, dictronite-coated ball bearings that improve the outgassing performance of the manipulator.

For the outer shaft, the manipulator can be outfitted with both ball bearings or slide bearings, depending on the specific requirements of the application.Rotary Type:

Single Shaft: Linear motion and continious rotation of a single shaft is the standard functionality of a sample transporter and is typically used for sample handling and sample parking.

Dual-Shaft, Single Rotary: For additional actuation capabilities for vacuum-side end effectors, like revolving sample carriers, pincers, or wafer lifting, a dual-shaft design with independent rotation of the inner shaft is necessary.

Dual-Shaft, Dual Rotary: For complete rotational freedom, dual-shaft manipulators can be outfitted with indpeendent rotation of both shafts.

The inner shaft rotation is used for additional actuation of in-vacuum tools, while the outer shaft carries andis capable of rotation the entire insert.

Viewing enlarged image:

Flange:

Heavy-Duty Sample Transporters are available with mounting flanges in the standard size DN40CF. Special flange sizes can be utilized in select cases, contact us for more details.

Retracted Length [mm]

Specifies the minimal length of the shaft extending from the DN40CF flange surface towards the vacuum side, while the manipulator shaft is fully retracted.

Linear Travel [mm]

The maximum travel distance of the Sample Transporter shaft. Added to the retracted length, this defines the shaft's maximum extension into the vacuum chamber.

Options:

HS Option - Hollow Shaft: For applications that require a lighter build or reduced thermal conductivity, this option replaces the standard shaft of the sample transporter with a tubular shaft. One typical application for this design is the sample insertion into cryogenic SPM systems.

Heavy-Duty Sample Transporter (DN40CF)

RM40-XXXX-YYYY

From3’500.00 CHF

Dual Shaft, Heavy-Duty Sample Transporter (DN40CF)

RMJ40-XXXX-YYYY / RMD40-XXXX-YYYY

From5’300.00 CHF

Dual Shaft, Dual Rotary, Heavy-Duty, Sample Transporter (DN40CF)

RMJG40-XXXX-YYYY / RMDG40-XXXX-YYYY

From6’300.00 CHF

Hollow Shaft, Heavy-Duty Sample Transporter (DN40CF)

RMHS40-XXXX-YYYY

From10’900.00 CHF