Electron Bombardment Heating

- Extreme High-Temperature Capability: Reaches up to ~2000°C for demanding applications.

- Efficient Energy Transfer: Direct electron bombardment ensures rapid heating.

- Customizable Configurations: Tailor systems with variable linear travel, rotation, and receiver orientation options.

What is Boralectric Heating?

Electron bombardment (E-Beam) heating is a high-performance technique that involves placing the sample plate under high voltage and bombarding it with an electron beam to generate intense heating. This method is particularly effective for applications requiring extreme temperatures, reaching up to ~2000°C.

Ferrovac’s E-Beam heating stages are designed for high-efficiency energy transfer, making them ideal for demanding UHV applications where rapid heating and high temperatures are required.

These heaters include a drawer style receiver, compatible with all standard Ferrovac flag style sample holders.

Ferrovac's E-beam heaters are available as standalone heating units, as well as complete, plug-and-play heating stations that come fully assembled with electrical feedthroughs, built-in temperature monitoring, as well as optional linear & rotational motion.

Typical Applications

Ferrovac Sample Transporters are available in various configurations to meet a wide range of applications, such as:

- High-Temperature Sample Annealing: Used in materials science and surface physics to modify surface properties at high temperatures.

- Thin Film Deposition (Evaporation Source): Providing intense heat for evaporating refractory metals and oxides in PVD (Physical Vapor Deposition) processes.

- Substrate Degassing: Removing adsorbed gases from refractory and metallic substrates before high-precision experiments or deposition processes.

- And much more…

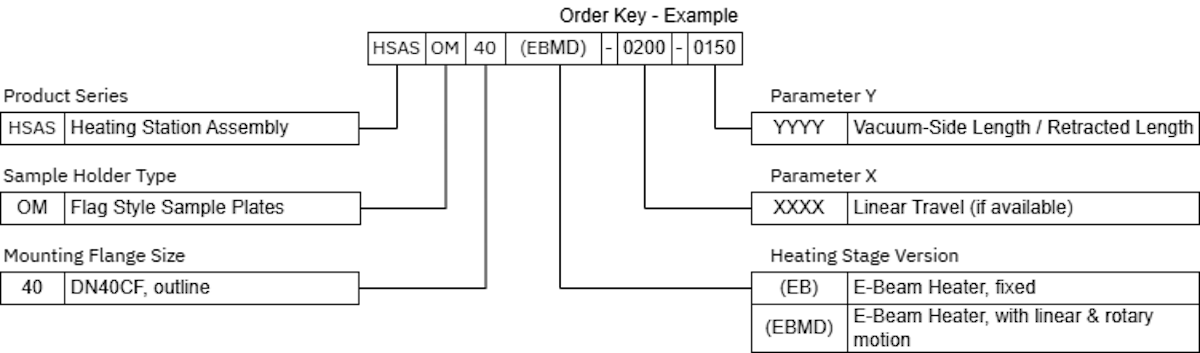

Product Code:

A fully configured heating station can be described & ordered with the following order code.

Viewing enlarged image:

Heating Station Product Series:

Heating Station Assembly: The full, ready-to-use heating station that includes vacuum-side wiring, electrical feedthroughs and mounting flange.

Sample Holder Type: This heating station is compatible with all Ferrovac Flag Style Sample Plates.

Mounting Flange Size: The entire heating station can be mounted to a single DN40CF flange.

Heating Stage Version:

(EB) Version - Fixed Stage

The stationary heating stage version reaches into the chamber by a customizable distance from the mounting flange.(EBMD) Version - Stage with Motion

This heating stage version is capable of linear & rotary motion. The linear travel and the retracted length can be customized.Linear Travel [mm]:

The maximum travel distance of the manipulator. Added to the retracted length, this defines the shaft's maximum extension into the vacuum chamber.

Retracted Length / Vacuum-Side Length [mm]:

Specifies the minimal length of the shaft extending from the DN40CF flange into the vacuum chamber.

If you require assistance in finding the right solution for your application, connect with Ferrovac Sales for expert advice.

Contact