Direct Current Heating

- Efficient Heating: Direct current flow enables fast temperature ramp-up.

- Easy Integration: Drawer-style design for seamless UHV system compatibility.

- High-Temperature Capability: Reaches up to ~1300°C, depending on setup.

What is Direct Current Heating?

Direct current heating, like the name implies, utilizes a direct current through the sample to heat it quickly and efficiently. This heating technique is extremely versatile and can be used in a very wide range of applications, but it requires the sample, or a sample holder with good a good thermal connection to the sample, to be electrically conductive.

If set-up correctly, Ferrovac direct current heaters can reach temperatures up to ~1300°C.

The Ferrovac direct current heaters come in the form of a drawer style receiver with electrical connection points that fit the flag style sample plate for DC heating.

For a complete plug-and-play solution, the direct current heating station provides a fully configured and wired product that can be mounted to a single DN40CF flange.

These heating stations include a thermocouple, all necessary in-vacuum wiring and electrical feedthroughs, as well as optional linear & rotational motion.Typical Applications

Ferrovac Sample Transporters are available in various configurations to meet a wide range of applications, such as:

- Semiconductor Surface Preparation: Frequently used in semiconductor research, for processes such as Si(111) 7×7 surface reconstruction.

- Thin Film Growth & Evaporation: DC heating can serve as a thermal evaporation source for metal deposition in thin film fabrication.

- Graphene Growth: Heating a metallic substrate (e.g., copper or nickel) to high temperatures to facilitate chemical vapor deposition (CVD) growth of graphene.

- And much more…

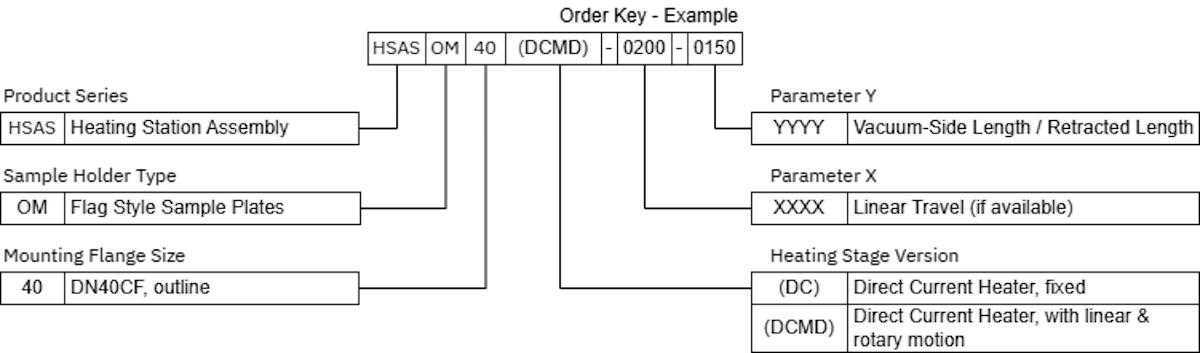

Product Code:

A fully configured heating station can be described & ordered with the following order code.

Viewing enlarged image:

Heating Station Product Series:

Heating Station Assembly: The full, ready-to-use heating station that includes vacuum-side wiring, electrical feedthroughs and mounting flange.

Sample Holder Type: This heating station is compatible with all Ferrovac Flag Style Sample Plates.

Mounting Flange Size: The entire heating station can be mounted to a single DN40CF flange.

Heating Stage Version:

(DC) Version - Fixed Stage

The stationary heating stage version reaches into the chamber by a customizable distance from the mounting flange.(DCMD) Version - Stage with Motion

This heating stage version is capable of linear & rotary motion. The linear travel and the retracted length can be customized.Linear Travel [mm]:

The maximum travel distance of the manipulator. Added to the retracted length, this defines the shaft's maximum extension into the vacuum chamber.

Retracted Length / Vacuum-Side Length [mm]:

Specifies the minimal length of the shaft extending from the DN40CF flange into the vacuum chamber.

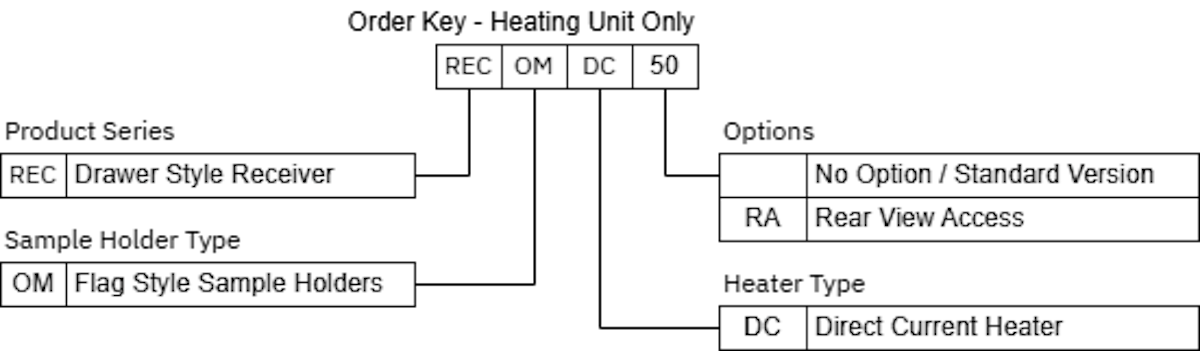

Single Heater Unit

Alternatively, a single heater unit can be purchased as follows.

Viewing enlarged image:

If you require assistance in finding the right solution for your application, connect with Ferrovac Sales for expert advice.

Contact

Direct Current Heating Drawer Style Receiver for DC Flag Style Plates

RECOMDC

From2’100.00 CHF

Direct Current Heating Receiver with Central Opening for Optical Access

RECOMDCRA

From3’100.00 CHF

DC Heating Station for SHOMDC Sample Heating Plates

HSASOM40(DC)-YYYY-ZZZZ

From9’500.00 CHF

DC Heating Station for SHOMDC Sample Heating Plates, with Linear Travel & Rotation

HSASOM40(DCMD)-XXXX-YYYY-ZZZZ

From10’900.00 CHF