Boomerax Z-Stage

- Ultra-Precise: Smooth linear motion with 2-micron resolution and integrated visual precision scales.

- Durable Design: Engineered for heavy-duty applications. Edge-welded bellows ensure exceptional leak tightness and long-term reliability.

- Long Range Application: Designed to maintain precision at very long travel distances.

- Automation Integration: Optional Ferrovac motorization & encoder components are readily available.

What is a Boomerax Z-Stage?

The Boomerax Z-Stage is a robust, high-precision positioning stage designed for ultra-high vacuum (UHV) applications.

It delivers smooth, exceptionally precise motion while maintaining vacuum integrity through its high-quality edge-welded bellows. The versatile construction allows seamless integration into complex systems, including Boomerax XY-axis shift modules and rotary platforms, enabling the setup of a complete XYZR manipulator.Why Choose Ferrovac Boomerax Manipulators?

The large-diameter micrometer heads provide 2-micron resolution via a vernier scale, ensuring fine positional accuracy. Additional customization options include motorization, optical or incremental encoders, adjustable limit switches, and load compensation constant force springs for enhanced control and automation.

Many of these optional components can be retrofitted onto existing Boomerax manipulators in the field.

This modularity and sturdy edge-welded bellow design makes the Boomerax Manipulator series a long-term investement for a wide range of applications.

Typical Applications

Ferrovac Boomerax manipulators are available in various configurations to meet a wide range of applications, such as:

- Automated Systems: Fully automated, highly precise sample exchange systems with multiple positioning axis.

- Cryogenic Sample Stages: Used in combination with LN2 cryostat inserts, incredible cryogenic, mobile sample stages are possible.

- Focal Point Positioning: Precise adjustement and positioning of sample stages and experiment focal points.

- And much more…

When combined with Boomerax Z-stage modules and rotary platforms, a fully modular and adaptable XYZR manipulation system for use in UHV environments can be built.

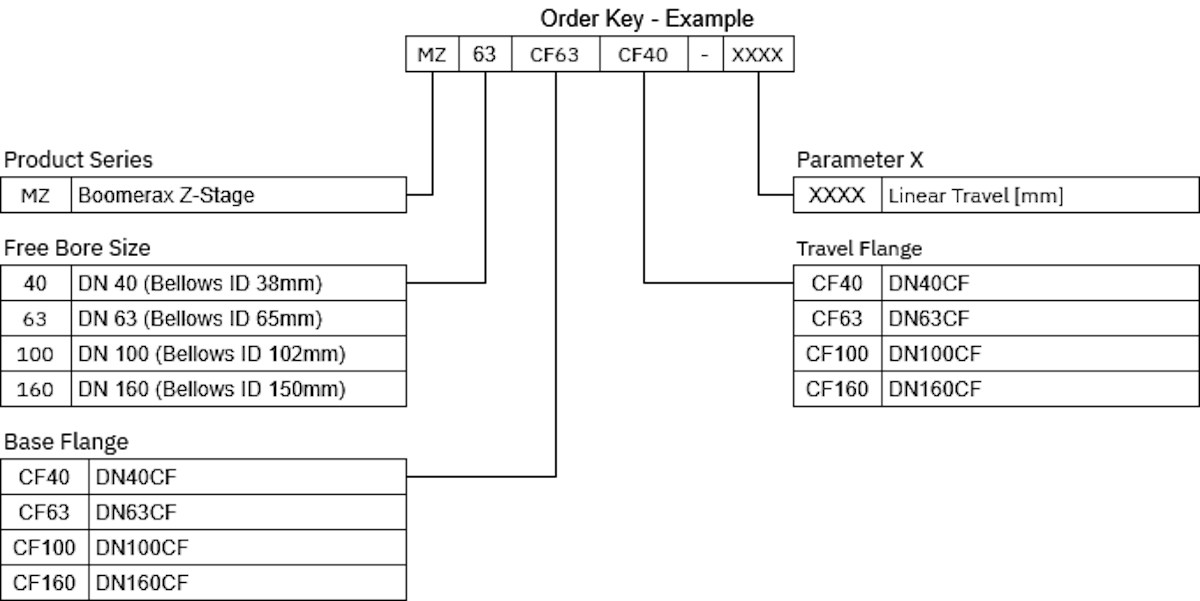

Product Code:

Viewing enlarged image:

Free Bore Size:

This Size category defines the bellows unit that is used and therefore is the determining factor for the insert size. More information on inserts and free bore size is listed below.

Base Flange:

The base flange size is most commonly chosen to fit the available bellows size (DN40CF, DN63CF, DN100CF, DN160CF). In select cases, different flange sizes may be chosen.

Travel Flange:

The travel flange can be adjusted with modular optional components to fit the chosen rotary feedthrough or insert flange.

Linear Travel [mm]:

The maximum travel distance of the manipulator. The overall length of the assembly is larger than this value, as travel flange moves along the spindle and compresses the bellows unit.

This must be taken into account when designing the length of the insert arm.Connect with Ferrovac sales for expert advice.

Contact