Contact

CH Switzerland

CH Switzerland

Ferrovac AG

Thurgauerstrasse 72

CH 8050 Zürich

Phone: +41 44 273 16 38

E-mail link?

Website http://www.ferrovac.com/

Service contact:

Phone: +41 44 273 16 38

E-mail link?

Our usual email response time

is 1-2 business days

WORLDWIDE eCommerce only

WORLDWIDE eCommerce only

UHV Store LLC

Bachweg 6

5467 FISIBACH

SWITZERLAND

E-mail link?

Website link?

GB United Kingdom &

GB United Kingdom &  IE Ireland

IE Ireland

LewVac

Unit F2 Ote Hall Farm

Janes Lane

Burgess Hill

RH15 0SR

Phone: +44 (0)1444 233372

Fax: +44 (0)1444 233392

E-mail link?

Website link?

CN China

CN China

BE-INSTRUMENTS TRADING CO., LTD.

北京埃伯仪器贸易有限公司

13th Floor, Room 10, Air China Plaza

No. 36, Xiaoyun Road

Chaoyang District, Beijing (P.R. China)

地址:北京市朝阳区霄云路36号国航大厦13层10号房间

Phone: +86 (0)10-806 983 56

Fax: +86 (0)10-806 983 59

E-mail link?

Website link?

JP Japan

JP Japan

TEC Corporation

Keigo Matsuda

7-19-26-213 Oizumigakuen-cho

Nerima-ku, Tokyo 178-0061, JAPAN

Phone: +81-3-5935-1060

Fax: +81-3-5935-1070

E-mail link?

Website link?

KR Korea, Republic of

KR Korea, Republic of

INA Korea Co.,Ltd.

DK B/D, 27-4, Gongduck-Dong,

Mapo-Gu, Seoul 121-020 Korea

Tel : +82-2-714-5456

Fax: +82-2-714-5457

E-mail link?

Website link?

Website link?

SG Singapore &

SG Singapore &  MY Malaysia &

MY Malaysia &  ID Indonesia

ID Indonesia

ARC Sciences Pte Ltd.

12 Lorong Bakar Batu, #06-07

Singapore 348745

Phone: +65 6296 7828

Website: link?

TW Taiwan

TW Taiwan

Shumotek Corp.

Add. No. 111, Jiabei 1st St.,

Zhunan Township

Miaoli County 35058, Taiwan (R.O.C.)

Cellphone : +886-919-706-759

Phone: +886-37-612810

Fax: +886-37-612811

E-mail link?

Website: link?

US United States

US United States

United Mineral & Chemical Corp.

160 Chubb Avenue, Suite 206

Lyndhurst, NJ 07071

Tel: +1 201-507-3300

Cell: +1 973-864-0537

E-mail link?

Website: link?

AU Australia &

AU Australia &  NZ New Zealand

NZ New Zealand

Ferrovac AG

Thurgauerstrasse 72

CH 8050 Zürich

Phone: +41 44 273 16 38

E-mail link?

Website: http://www.ferrovac.com/

All other countries, please contact our headquarters in Switzerland

Projects

On this page we would like to provide a more in-depth look at our products and also present ongoing and completed projects. Our complete product range can be found in the:

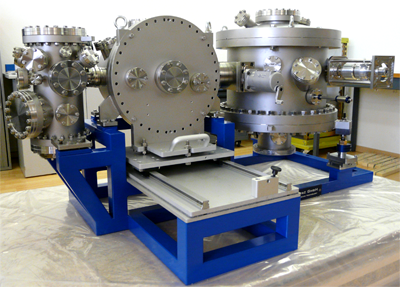

SLAPXPS :: Solid-Liquid Ambient Pressure XPS Endstation with Analysis Chamber Module

SLAPXPS :: Solid-Liquid Ambient Pressure XPS Endstation with Analysis Chamber Module

Swiss Light Source Beamline: NanoXAS

"We ordered a custom-based ambient pressure XPS endstation from Ferrovac to study solid-liquid interfaces. Ferrovac did an excellent job both in terms of engineering and assembly and delivered the product on time. This endstation is very productive from the very first day it was connected to the synchrotron at the Swiss Light Source."

Z. Novotny, Scientist, Paul Scherrer Institute/University of Zuerich

Sample Handling System for Cryogenic SNOM :: UC San Diego

link?The finishing touches to an all-round sample handling and storage solution were realized mid-year with delivery to the University of California following soon after.

The system was developed in close collaboration between the engineering department of Ferrovac and Alexander S. McLeod and Michael Goldflam of the Department of Physics at UC San Diego.

Once fully assembled and operative, the first results and feedback were altogether positive:

"Behold, [...] an infrared image now from our microscope, showing conductive metallic regions percolating during a metal-insulator transition in an oxide film at ~160K. Suffice to say we are happy everything is working for us now with the RECOMECs, load-lock and wobblestick, this hardware is enhancing our productivity quite a lot!"

- A. McLeod, UC San Diego

link?

link?

Michael Goldflam and Alexander S. McLeod of the Basov Infrared Laboratory, UC San Diego

Developers and builders of the cryogenic scanning near-field optical microscope

Read more

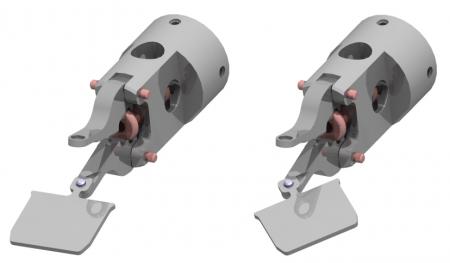

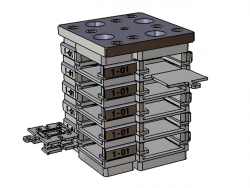

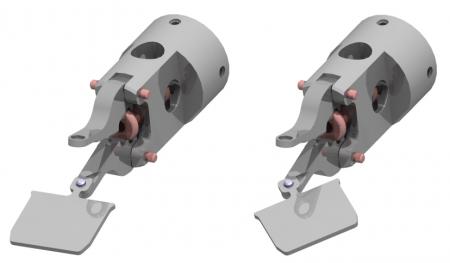

The system (pictured above) consists of a customized KS load lock cross and chamber, a WMG40 wobblestick with custom-made PGWMS pincer, a pair of MD linear/rotary feedthroughs equipped with eightfold RECOMSTACK sample storage stacks and the elementary RECOMEC13S receptacles and SHOMEC13 sample plates with electrical contacts.

The system (pictured above) consists of a customized KS load lock cross and chamber, a WMG40 wobblestick with custom-made PGWMS pincer, a pair of MD linear/rotary feedthroughs equipped with eightfold RECOMSTACK sample storage stacks and the elementary RECOMEC13S receptacles and SHOMEC13 sample plates with electrical contacts.

In very limited space, the approach to the interchangeable probe and sample plates is only possible at a 47° angle, with the probe also tipping forward. A special pincer design accounts for these issues, making access to and exchange of the samples a smooth affair.

By simply twisting the wobblestick to one or the other side and back, the sample plate is held either straight for exchange with either storage stack or at an exact 47° for access to the microscope.

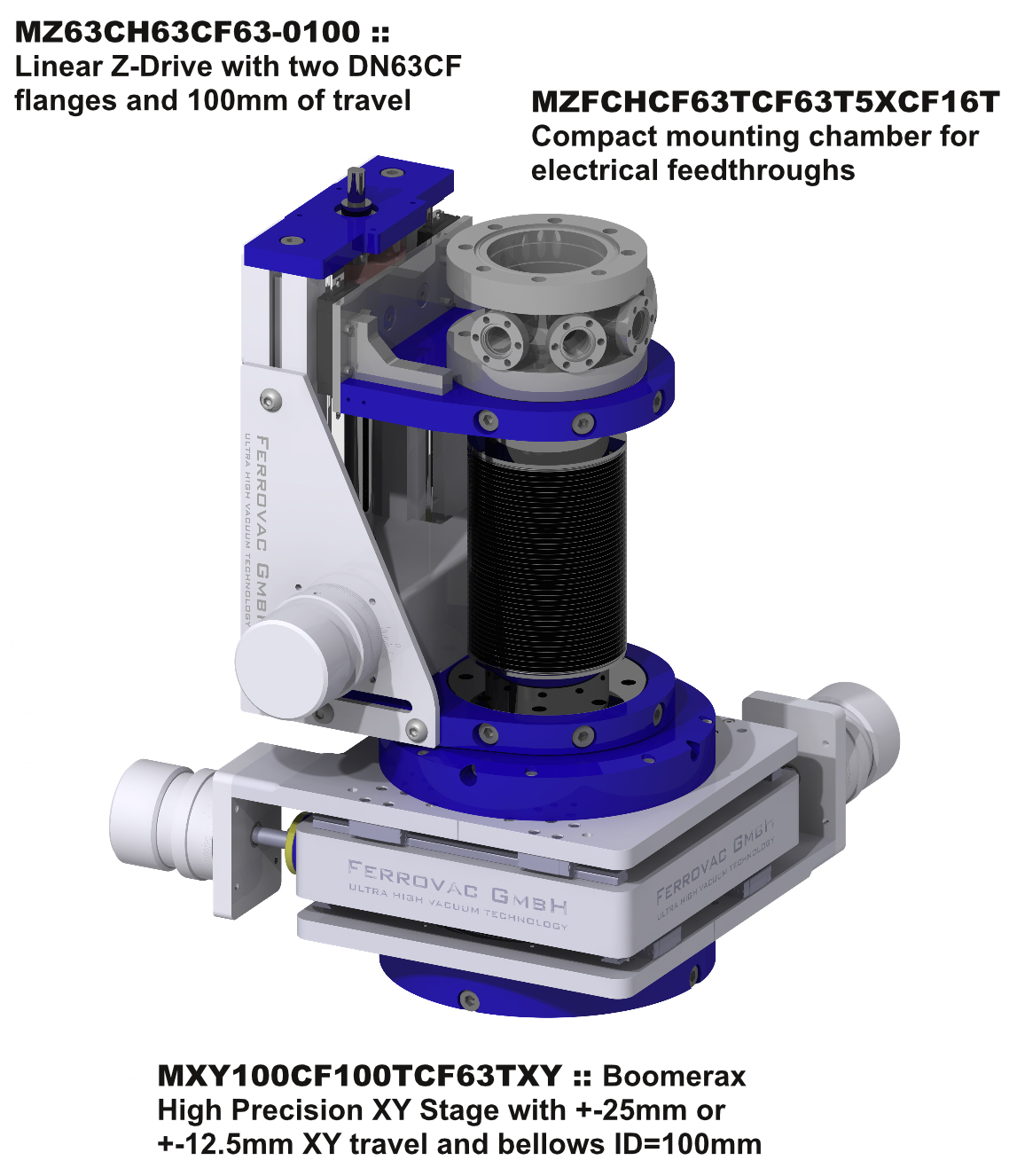

MXYZR :: XYZR Boomerax Manipulator Series

This configuration example provides every necessary degree of freedom for full control over your samples in a UHV environment and sample temperatures down to 10 Kelvin by combining a "Boomerax" high precision XY stage with our MZ linear Z-axis drive and incorporating a well-established and very stable Janis ST-400 continuous flow cryostat.

ST-400 He-Flow Cryostat :: As one of the the simplest methods of providing cooling in an ultra-high vacuum environment, the ST-400 has several features that are specific for UHV requirements.

MR63DPV552 Rotary Feedthrough :: This differentially pumped rotating platform provides the means of translating rotation through a vessel wall without losing vacuum integrity

MZ Z-Translator :: The optionally motorized linear Z-axis drive comes into play for accurate lifting and lowering. It's highest quality edge welded bellows fulfill the strictest requirements in terms of leak tightness and durability.

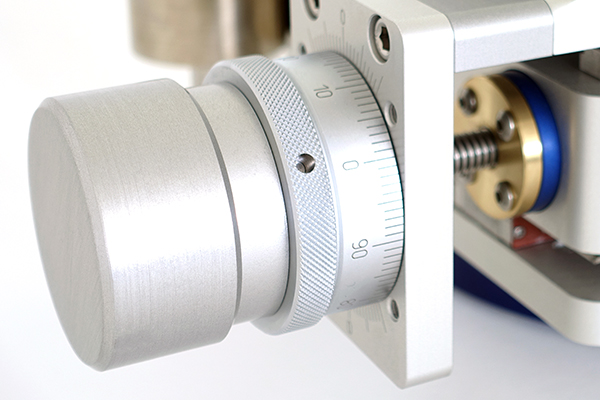

Boomerax MXY Module :: For smooth and exceptionally precise adjustment, it offers a resolution of 2 microns when manually driven and even higher resolutions when motorized.

Sizes and Options

- Mounting Flange Sizes: DN16CF, DN40CF, DN63CF, DN100CF, DN160CF

- Travelling Flange Sizes: DN16CF, DN40CF, DN63CF, DN100CF, DN160CF

- Limiteable Travel Distances

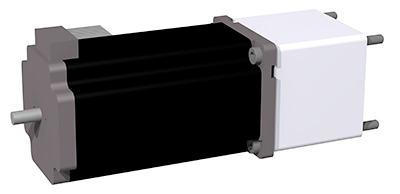

- Motorization Options Available for All Sizes

- Tilt: 2° in Any Desired Axis

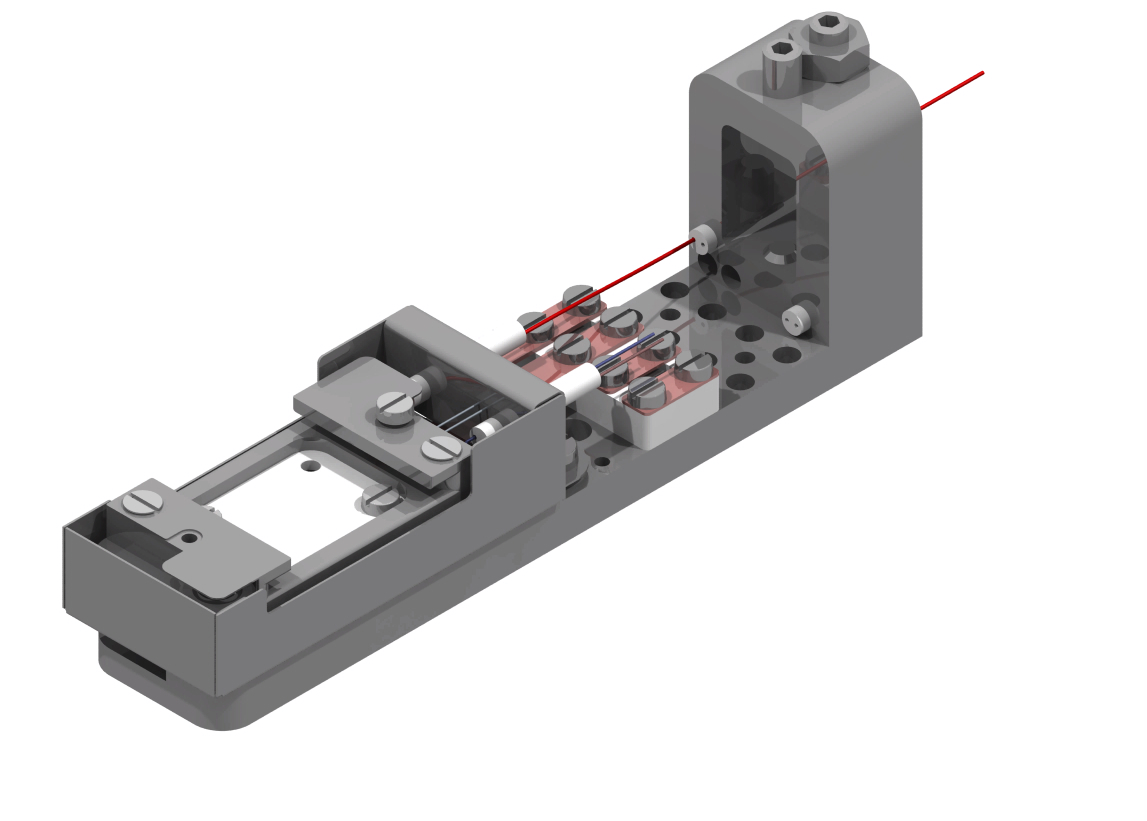

Sample Environment :: Sample Heating Stage assembly for flag style sample plates, featuring a standard rectangular PBN/PG heater.

Further example of Boomerax XYZ Stage, with Chamber for Electrical Feedthroughs

Manual or Motorized Actuation Alternatives for XY Stage ::

Heater assembly for direct current heating of SHOMDC sample holders

March 2017

Complementing our heating solutions is the recently updated HSASM40-MD16(TS)-TSMDH-HSMDDCOM heater assembly for direct current heating of SHOMDC sample holders.

Customizeable in it's lengths of travel and retraction, it's main element is the sample heating stage that's integrated into a complete assembly including a special DN40CF flange with linear/rotary as well as an electrical feedthrough.

For more information...

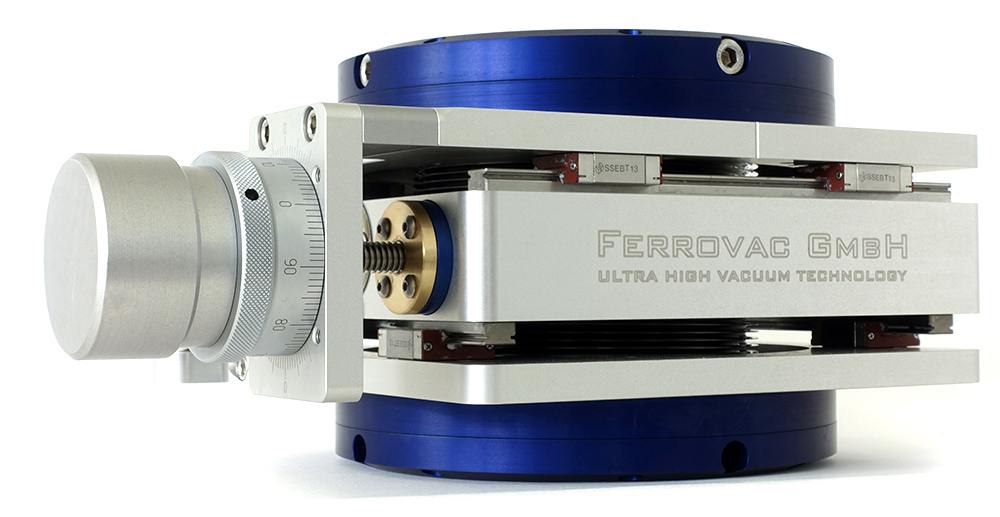

Mini NexGeneration UHV Suitcase

September 2016

From small to mini!

From small to mini!

We have developed an even smaller, lighter and more cost efficient version of our UHV suitcase. The VSN40M is equally reliable yet especially practical wherever space is at a premium.

The Mini NexGeneration UHV Suitcase is the ideal solution for carrying and transferring multiple samples at once under true UHV conditions from one instrument to another. The samples are held in a storage mechanism such as a stack of receptacles or a carousel. Should only a single sample holder need to be stored and transferred, this is also possible using a pincer grip, fork or similar instead of the storage option.

Just like the standard size UHV suitcase, the VSN40M is designed as a modular concept so that it can be adapted to suit your specific requirements.

For more information...

Sample Holder for Single Crystals

May 2016

As an example for a flag style sample holder for single crystals, the SHOMCH can be individually adapted to suit other monocrystalline types.

This special flag style sample holder simplifies the process of mounting single crystals (type K005), it's four slits in the retaining plate ensuring safe and level clamping.

If you use another single crystal type and/or need other dimensions, please do not hesitate to contact us.

For more information...

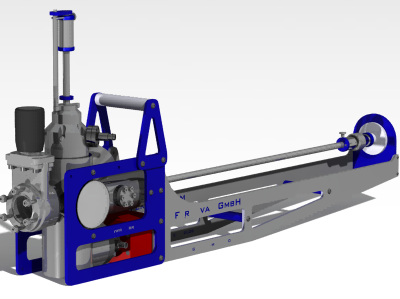

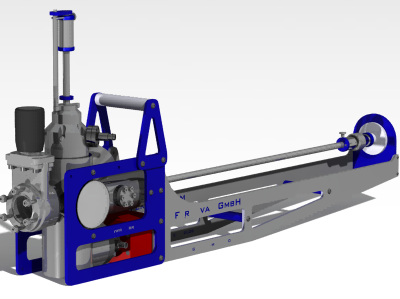

Hollow Shaft Sample Transporter with In-Vacuum Brake and Belt Drive

March 2016

March 2016

The RMHS40-IVBR-TSRMBD serves as a vertically mounted manipulator, commonly used for sample insertion into cryogenic SPM's.

The layout of these systems calls for long travel and precise manipulation.

The RMHS40 sample transporter features a specially treated hollow shaft that offers the necessary straightness, lighter weight and crucially it also avoids excessive thermal conduction.

Strongly recommended for safety reasons is the inclusion of an IVBR in-vacuum brake that prevents the inner shaft from suddenly dropping, should the magnetic coupling be let go by accident.

Facilitating the handling of such long sample transporters, the TSRMBD belt drive provides quick elevation over longer distances using it's belt. Two hand wheels enable precise linear as well as rotary positioning.

For more information...

Pictured below: IVBR In-Vacuum Brake

Application example (with UHV cube) shown: Scanning tunneling microscope setup operating in UHV, very low temperature (T<0.1K) and high magnetic field (B>15T). The hollow shaft, belt-driven sample transporter by Ferrovac enables top-loading of the sample and tip holders from the transfer chamber (UHV cube) down to the STM head.

Engineering: Dominique Grand (Institut Néel, CNRS & Université Grenoble Alpes)

PI: Benjamin Sacépé (Institut Néel, CNRS & Université Grenoble Alpes)

Hexapod Port Aligners

January/February 2016

January/February 2016

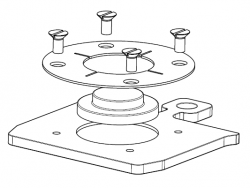

Used to align transfer axes of manipulator-to-chamber or chamber-to-chamber systems, port aligners are indispensable for most sample manipulations and transfer mechanics in UHV.

While all types of port aligner allow for angular and linear adjustments and compensation, the "HEX" models additionally enable lateral axis displacement.

Thanks to this enhanced flexibility, the axis of for example a sample transporter can be aligned with two different sample exchange positions in just one setting.

Hexapod port aligners are also especially sturdy.

For more information...

A great specific example of their implementation is by Imagine Optic, who have made our PA63HEX a standard part of their HASO EUV wavefront sensors (pictured below):

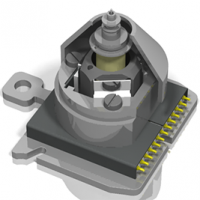

Receivers for SHOM flag style sample plates

Receivers for SHOM flag style sample plates

December 2015

December 2015

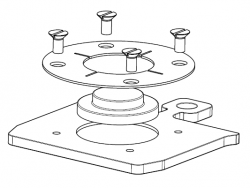

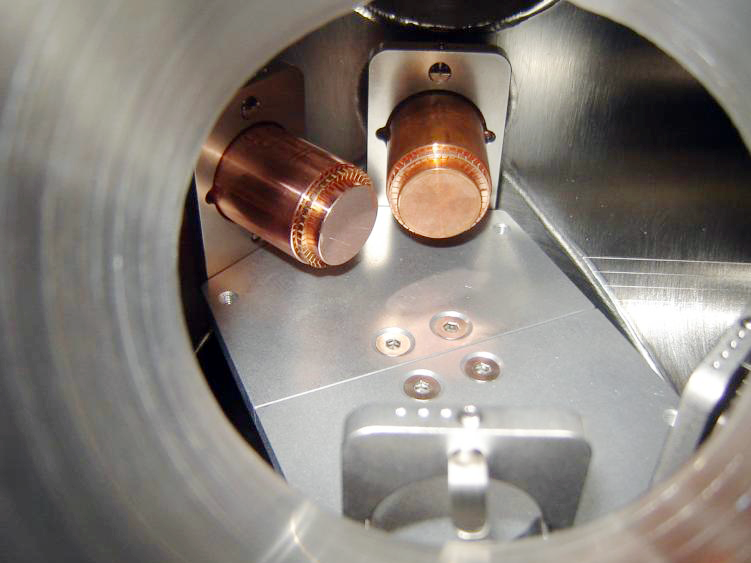

Our RECOM receivers are a utilitarian component for UHV systems that operate with SHOM flag style sample plates.

Machined from a solid block, they are available in a variety of shapes and materials to suit specific requirements like high heat resistance or non-ferromagneticity. We also supply matching SHOM plates in a great variety of materials.

Secured in the RECOM by leaf sprung Ruby spheres, the sample plates glide over these point contacts with very low friction.

RECOMs are the fundamental building block for a whole host of sample storage solutions such as revolving carriers for SHOM plates.

Please contact us to find your matching off the shelf or customized sample plate receiver and/or storage solution.

For more information...

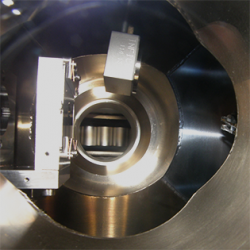

The pictured rotatable sample storage is a customized solution with 6 vertically mounted RECOM sample plate receivers

SwissFEL :: Energy Collimator

June 2015

June 2015

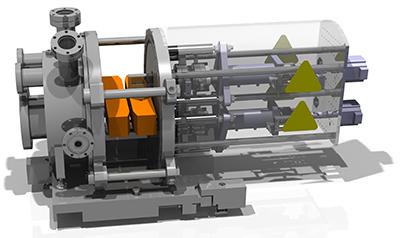

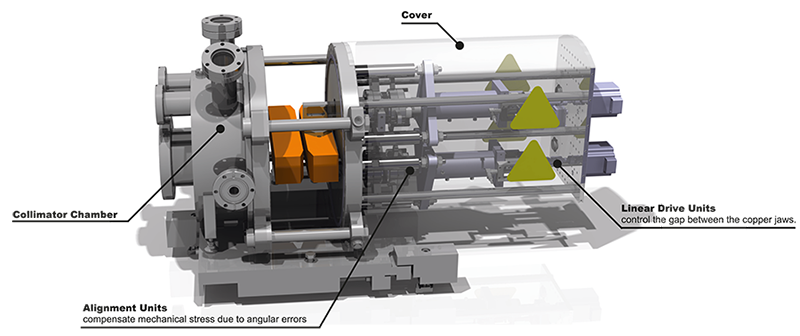

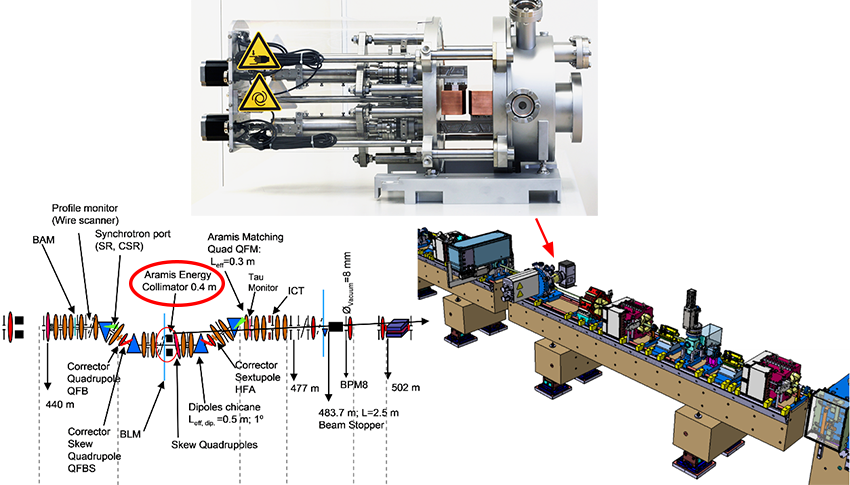

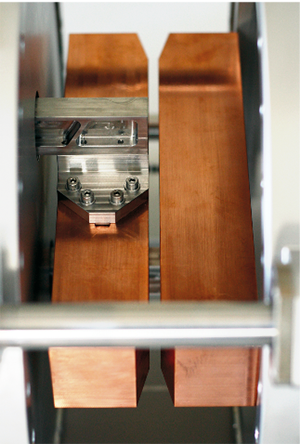

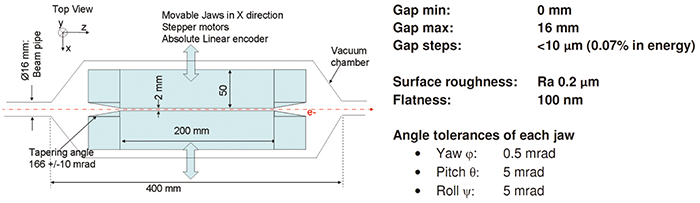

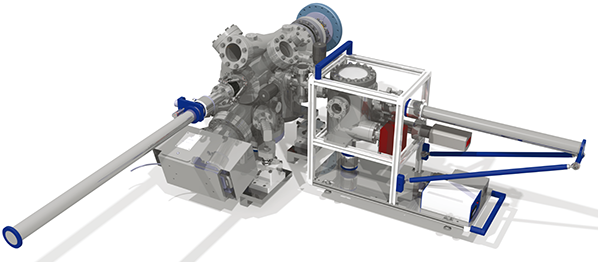

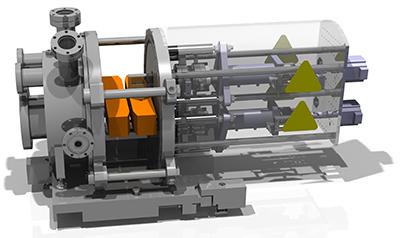

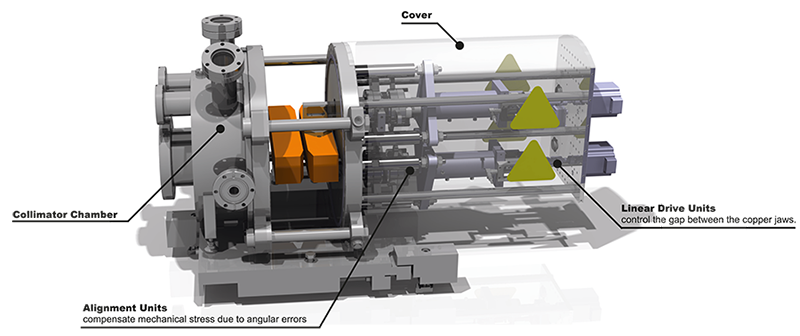

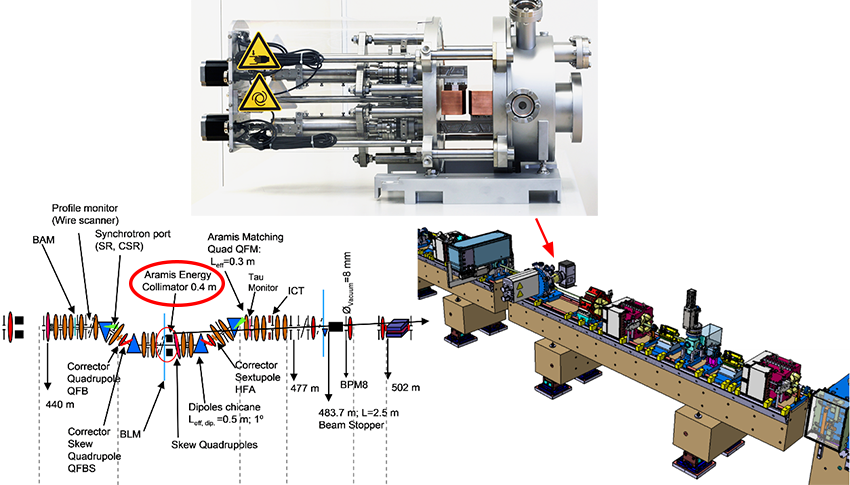

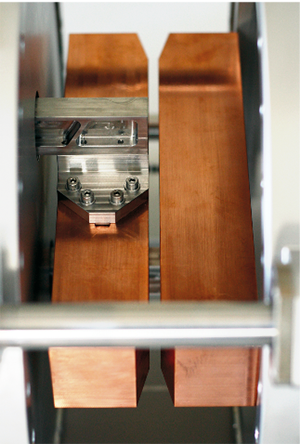

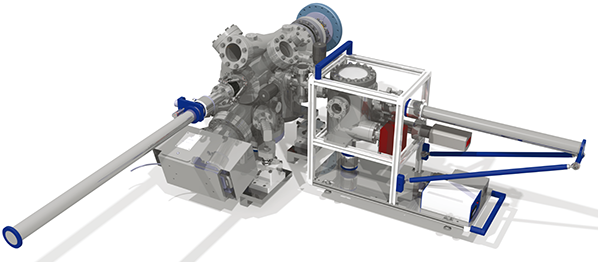

The HOENCOL energy collimator presented here was developed for the Swiss Free Electron Laser facility (SwissFEL) in close collaboration with the Paul Scherrer Institute. It consists of four magnetic dipoles with a collimator block system installed between the two central dipoles.

The energy collimator acts as a filter to protect the undulator line from parasitic electrons.

Read more

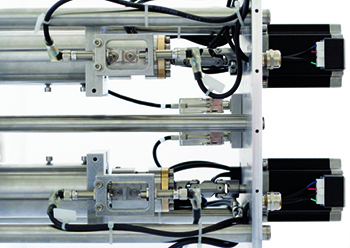

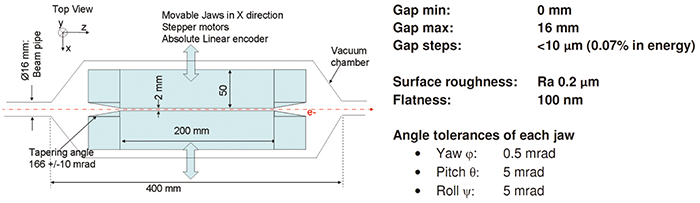

In order to vary the energy acceptance of the system, two motorized linear drive units move the shielding blocks along the horizontal axis perpendicular to the direction of the e-beam.

Alignment units

In order to resolve mechanical stress in the process of opening/closing the gap with the linear drives, possible angular errors are compensated by the alignment units. These consist of massive triangular plates held by three sturdy steel studs which are used for the initial alignment.

The edge welded belows allow for the necessary angular freedom.

Linear drive units

Due to potential electromagnetic disturbances caused by the stepper motors, these are placed 0.5 m away from the electron beam axis.

With an accuracy of less than 1 micron, an integrated linear encoder measures the linear displacement of the alignment unit.

Linear force is transmitted via torque shafts to protect the alignment units' belows from distortion.

Energy Collimator Location

Schematic Layout of SwissFEL Aramis beamline (left) and setup of various components on it's girder (right), showing the position of the energy collimator.

Energy Collimator Specifications

Energy Collimator Specifications

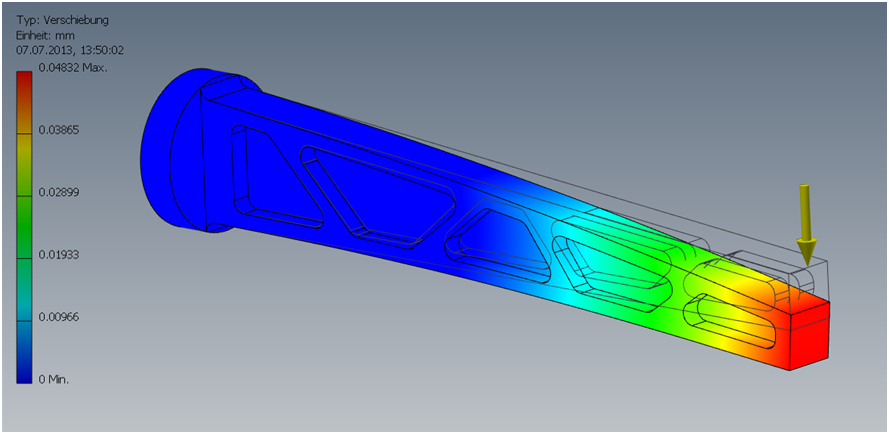

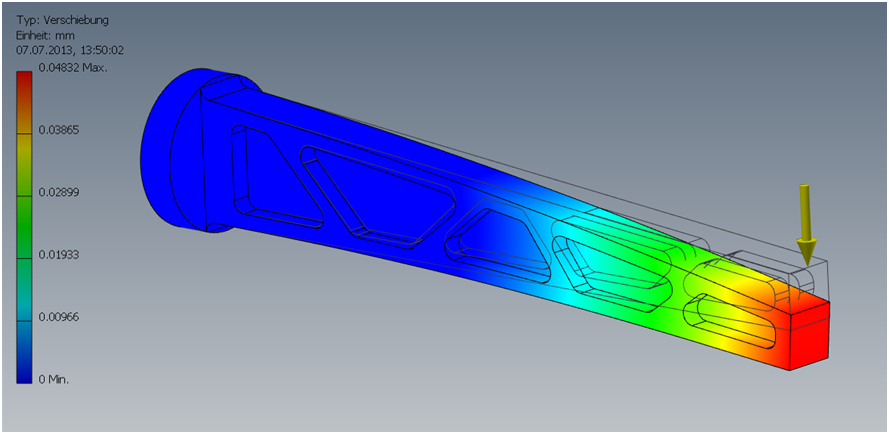

In order not to affect the beam quality, the surface and positioning of the two motorized shielding blocks must fulfil the high requirements specified below. The support beams and their supporting structure were laid out with an extreme stiffness using FEM (finite element method) to optimize shape and pocket geometry.

This simulation shows a support beam hanging freely without any base and with a 7kg load. In an overscaled representation, the displacement of the tip is calculated to be less than 0.05 mm.

This simulation shows a support beam hanging freely without any base and with a 7kg load. In an overscaled representation, the displacement of the tip is calculated to be less than 0.05 mm.

If you would like more information please contact us with any questions you may have at

link?.

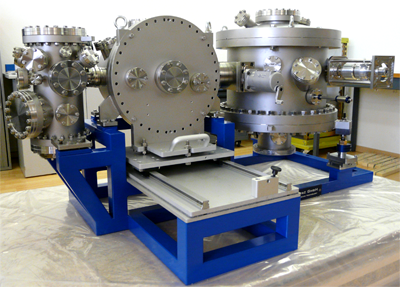

SwissFEL :: Photocathode Preparation and Load-Lock System

May 2015

May 2015

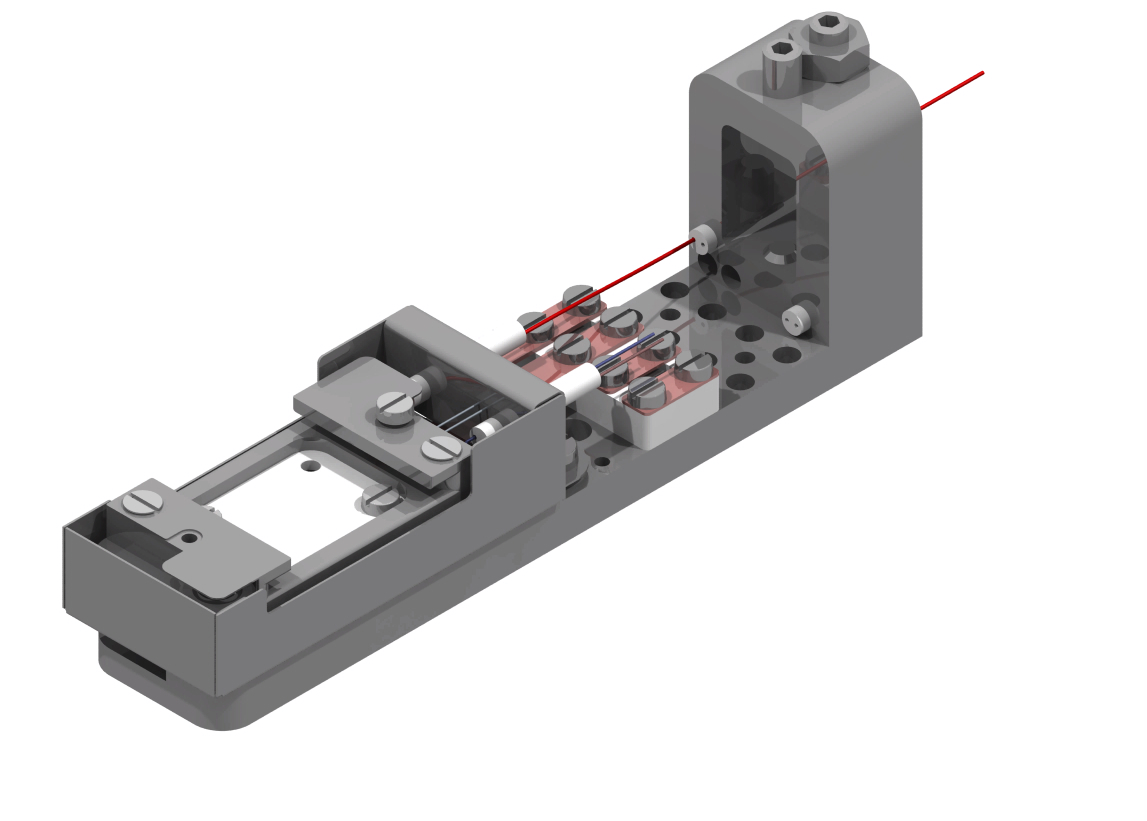

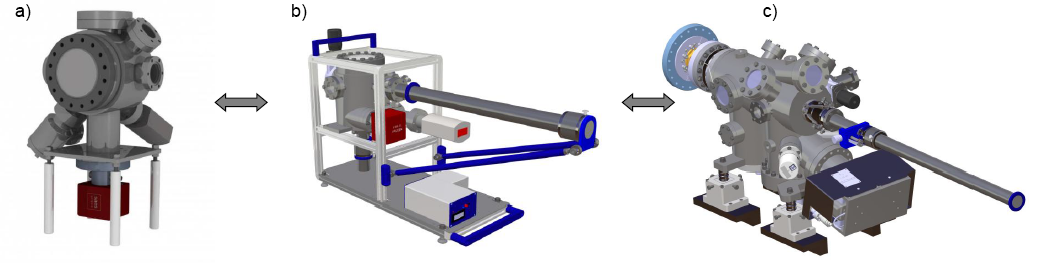

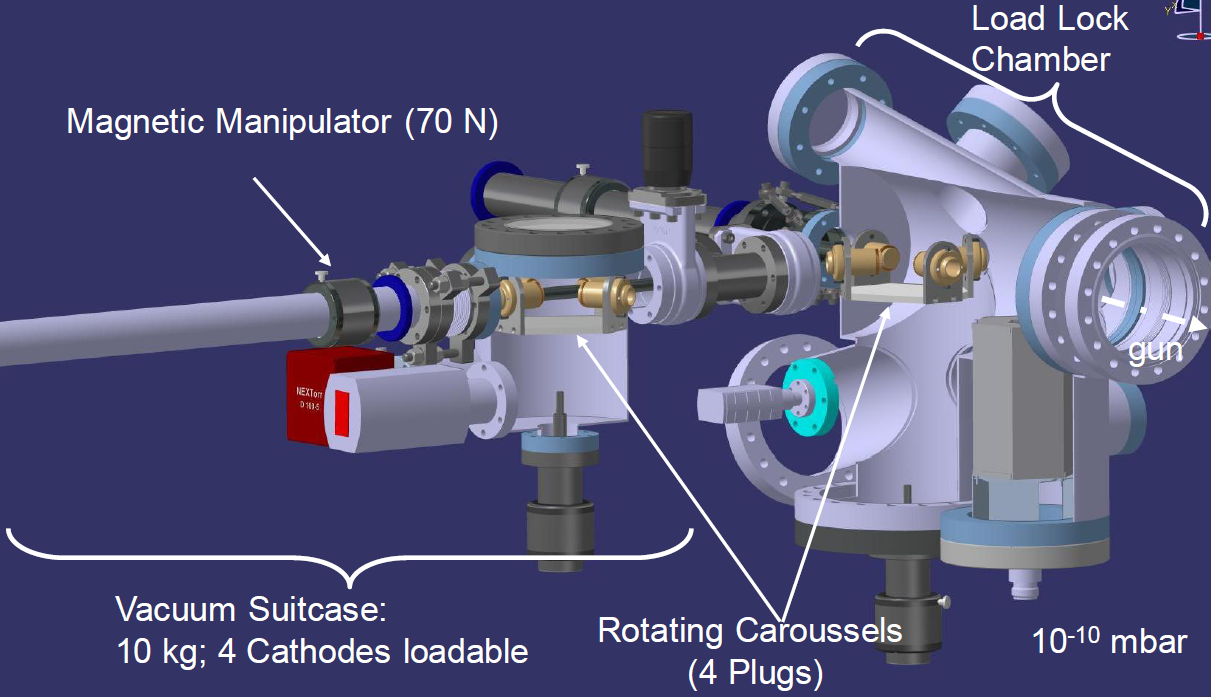

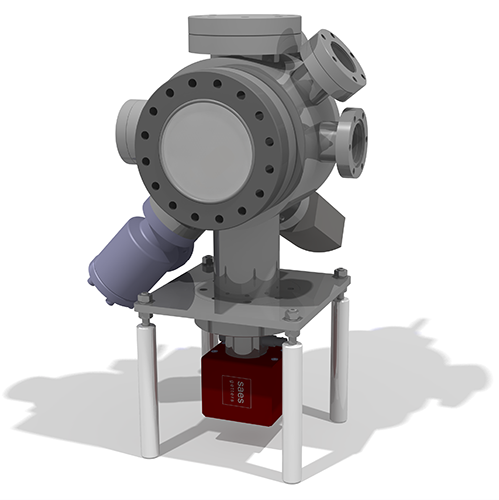

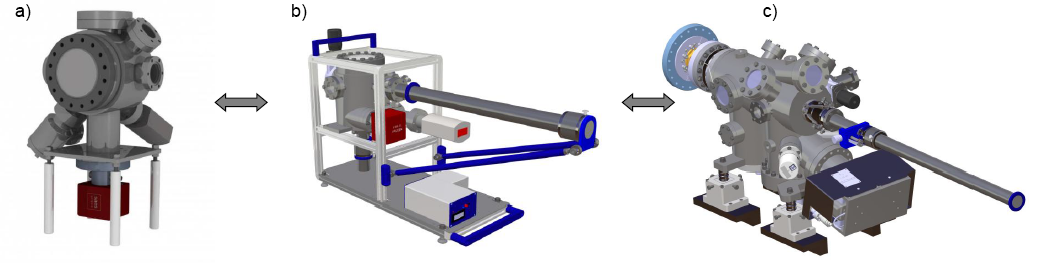

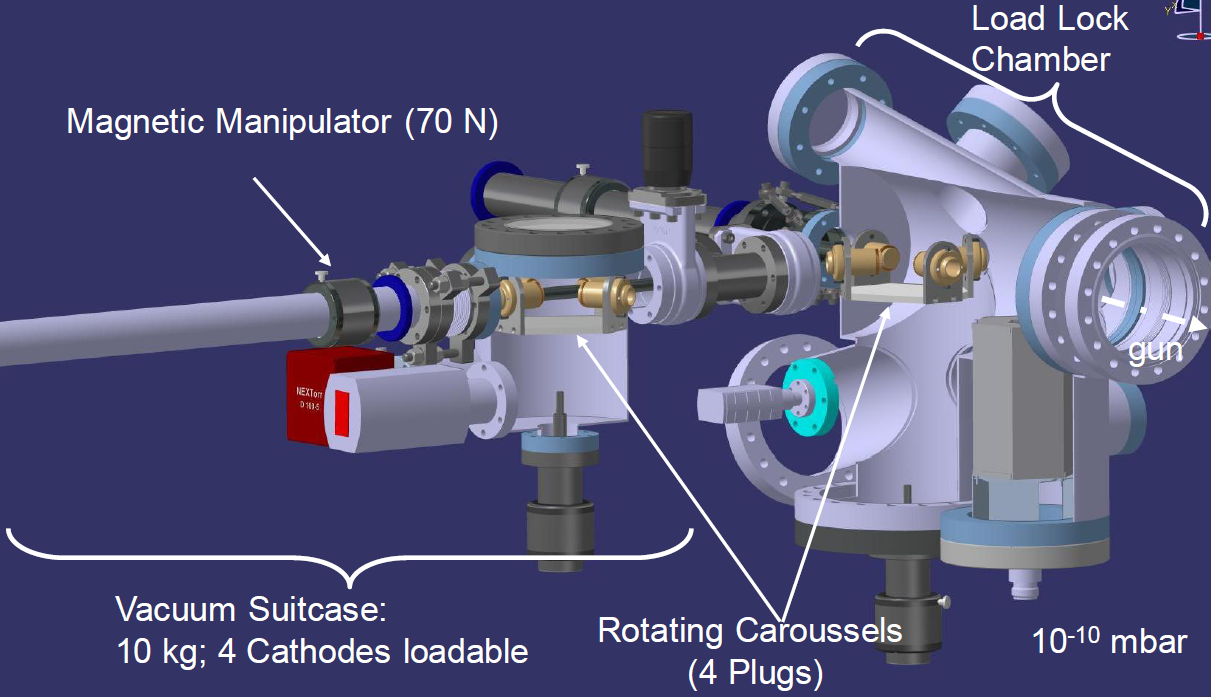

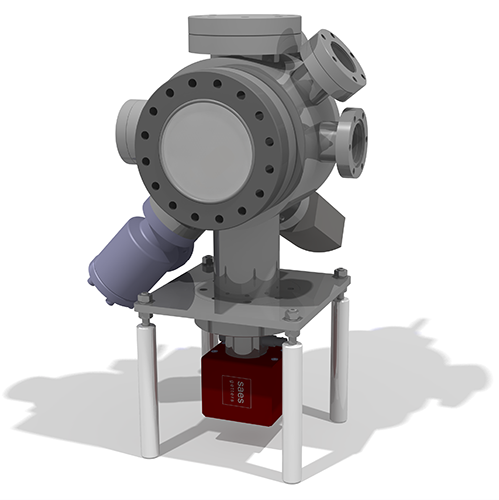

The PCPLS is a novel cathode preparation and loading system designed and built for the Swiss Free Electron Laser facility (SwissFEL) at PSI.

It enables the preparation and exchange of the RF photogun's cathode without breaking the UHV chain. A prerequesite for maintaining the quality of the cathode surface, which is essential.

Read more

The SwissFEL electron source is an RF photo-injector in which the photo-cathode plug can be exchanged, all under UHV conditions. Without a load-lock, the cathode exchange takes about one week and the cathode surface gets contaminated in the atmosphere during installation, leading to unpredictable quantum efficiency (QE) fluctuations.

These time and contamination issues motivated the construction of a load lock system to prepare and insert cathodes into the photo-injector, doing away with the need for venting the gun. Now using the vacuum suitcase for the cathode exchange between the preparation chamber and the gun loading chamber, the exchange requires only half a day (including RF conditioning of the new cathode, tested on Cu_17).

The cathode loading system consists of three chambers:

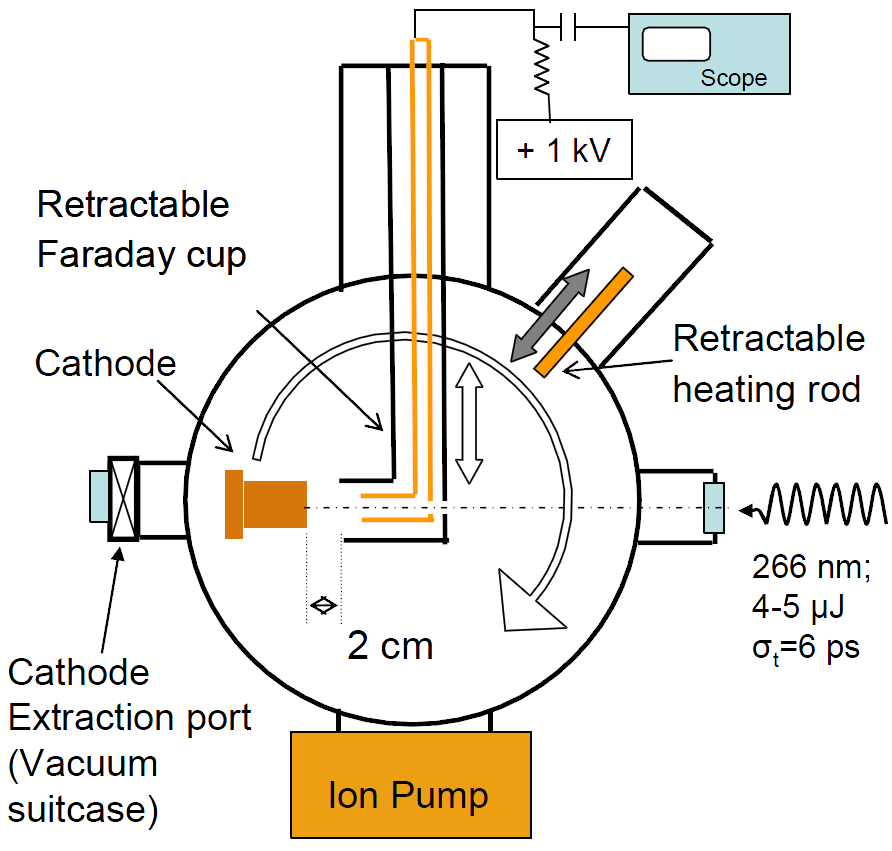

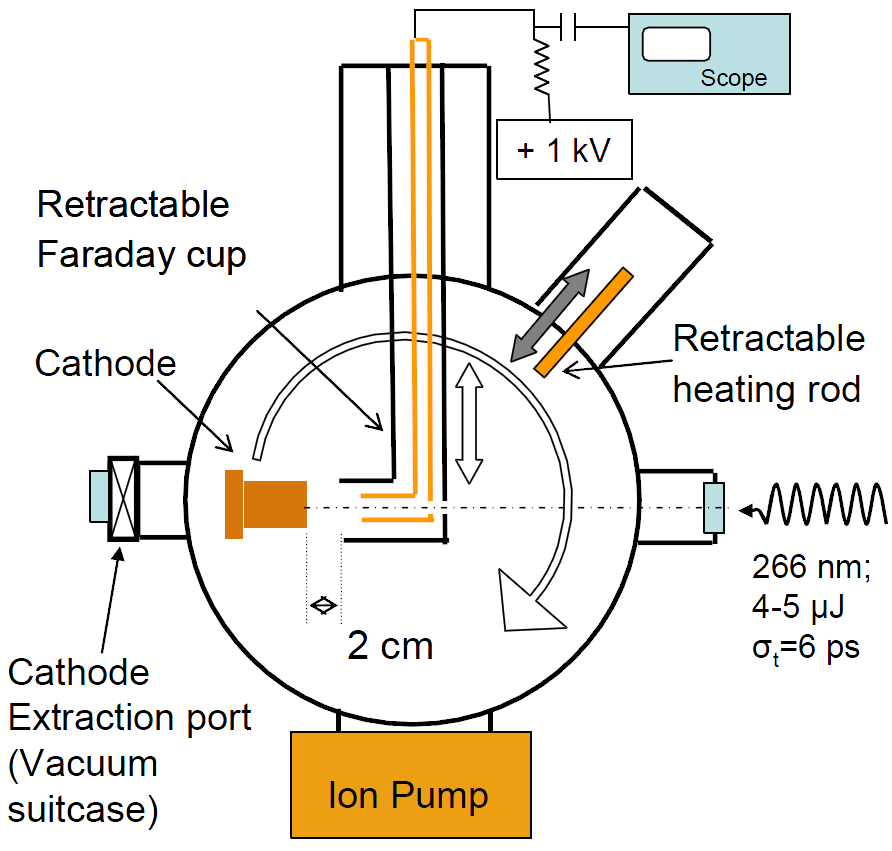

- a) Preparation chamber where cathodes can be cleaned, annealed and where the quantum efficiency (QE) can be checked.

- b) Vacuum suitcase where cathode plugs can be loaded from preparation chamber and transported to the gun.

- c) Gun loading chamber which is permanently attached to the gun and in which cathodes can be transferred from vacuum suitcase to the gun backplane.

This three-part system allows the preparation of the cathode surface with methods like annealing. The QE can be checked with a laser and the plug can be inserted into the gun without breaking the vacuum. This will eventually allow the use of semiconductor cathodes like Cs2Te.

The PCPLS system was successfully installed and tested at the SwissFEL injector Test Facility (SITF).

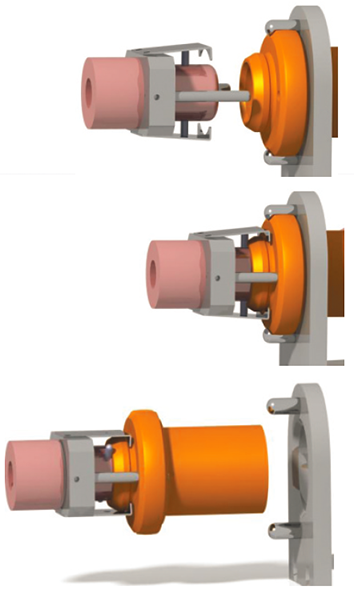

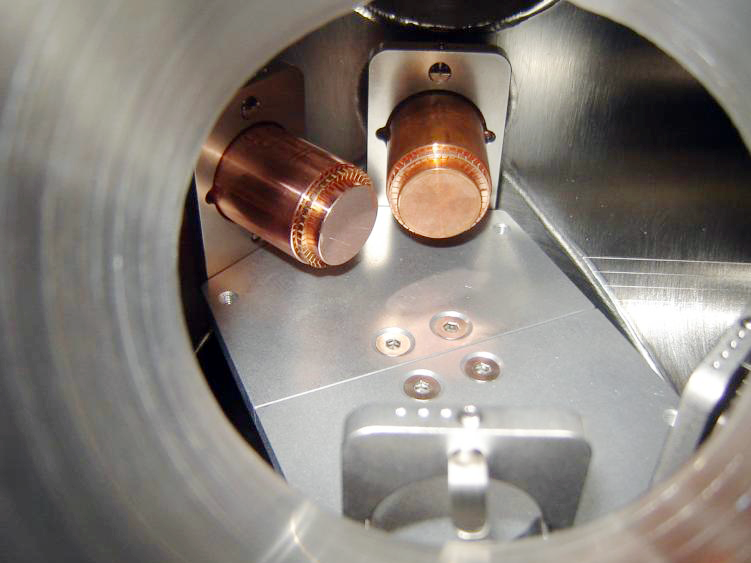

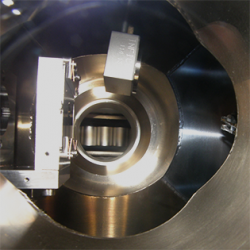

Storage carousel and grabbing principle

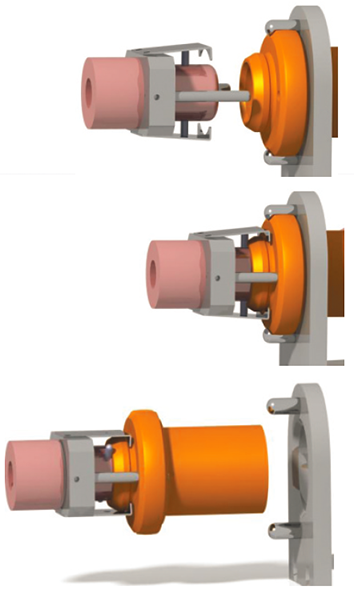

A magnetically coupled manipulator arm can grab the plug (right) out of a parking holder and safely transfer it linearly over half a meter distance under ultra high vacuum. In each of the 3 chambers a rotatable carousel (below) can hold up to 4 cathode plugs.

A magnetically coupled manipulator arm can grab the plug (right) out of a parking holder and safely transfer it linearly over half a meter distance under ultra high vacuum. In each of the 3 chambers a rotatable carousel (below) can hold up to 4 cathode plugs.

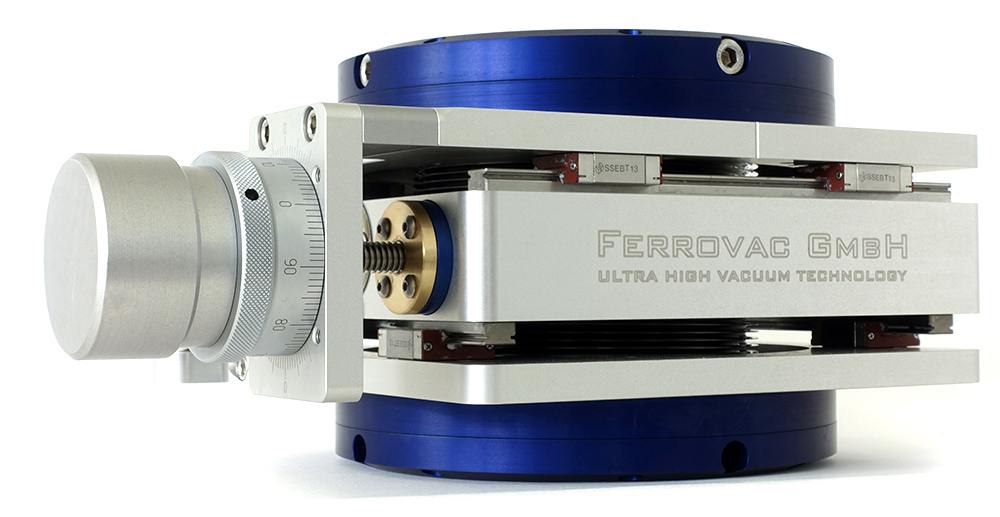

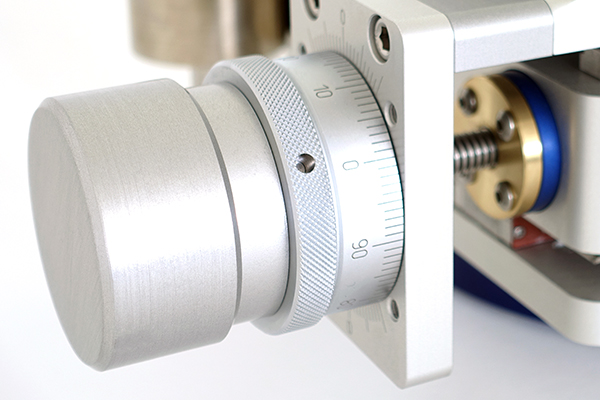

The figure to the right shows how the vacuum suitcase is connected to the gun loading chamber. The fine adjustment knob of the magnetically coupled manipulator keeps the cathode pushed into the gun during operation.

The figure to the right shows how the vacuum suitcase is connected to the gun loading chamber. The fine adjustment knob of the magnetically coupled manipulator keeps the cathode pushed into the gun during operation.

Cathode preparation

The quantum efficiency of the cathodes depends on three theoretical parameters: the work function, the surface reflectivity and the local electric field (for a given laser wavelength). Contamination and roughness directly affect these parameters. The PPLS enables optimized preparation procedures and actions for the cathodes.

The quantum efficiency of the cathodes depends on three theoretical parameters: the work function, the surface reflectivity and the local electric field (for a given laser wavelength). Contamination and roughness directly affect these parameters. The PPLS enables optimized preparation procedures and actions for the cathodes.

Cathode surface cleaning is done in the preparation chamber. The most effective way to remove surface contaminants is to heat up the cathode plug for several hours. The preparation chamber is equipped with a heating rod which can be directly inserted into the back of the cathode plug. Thanks to the vacuum suitcase, the cathode is protected from exposure to atmosphere during transfer. Therefore preparation processes such as Dicaesium Telluride vapor deposition can be included.

The deposition chamber is equipped with an easily exchangeable aperture in front of the cathode (for variation of the deposition area)

and a quartz micro-balance. The cathode is loaded from the left and the evaporation source from the right.

If you would like more information please contact us with any questions you may have at link?.

Motorized Sample Transporters

April 2015

April 2015

Motorization of manipulators provides reliable, safe and precise movement, positioning and handling. Implemented in our motorized sample transporters are the necessary prerequesites: a fine step resolution and a sturdy construction.

Where different users operate, automation is especially advantageous and also saves valuable working time.

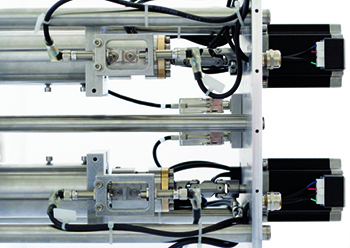

Shown in the video below is a stepper motor-driven linear drive for RM and GMD sample transporters. The motorized drive allows for automatic and reproducible extension of the shaft. Rotary motion is done manually.

Pictured right is a motorized linear and double rotary drive with pincer grip for SHOM sample plates. The separate rotation of each shaft enhances operation of the pincer by being able to open/close and also rotate it.

Available versions...

Motorized Linear- & Rotary Manipulator

December 2014

Linear motion of the shaft is controlled by a precision motorized spindle that is coupled to the outer magnet. The shaft is rotated via gear wheels that transfer the motion from a second stepper motor.

For more information, please contact us directly.

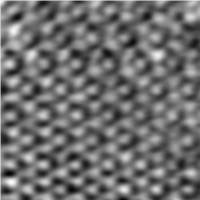

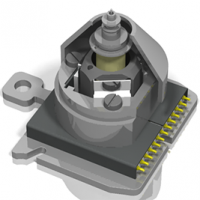

Portable Scanning Probe Microscope in a UHV-Suitcase

October 2014

Product VSPROBE2 not available.

Product VSPROBE2 not available.

|

| Atomically resolved Graphene on Ni thin film, SiO2/Si substrate. |

|

| SHOMEC13(EBL1) Scan Head |

Project History

April 2014 - RSI publication: " Design and performance of AERHA, a high acceptance high resolution soft x-ray

spectrometer"

By: Sorin G. Chiuzbian, Coryn F. Hague, Antoine Avila, Renaud Delaunay, Nicolas Jaouen, Maurizio Sacchi,

François Polack, Muriel Thomasset, Bruno Lagarde, Alessandro Nicolaou, Stefania Brignolo, Cédric Baumier, Jan Lüning, and Jean-Michel Mariot

Ferrovac would like to thank the authors for mentioning us in the acknowledgment.

Citation: Review of Scientific Instruments 85, 043108 (2014); doi: 10.1063/1.4871362

View online: link?

View Table of Contents: http://scitation.aip.org/content/aip/journal/rsi/85/4?ver=pdfcov

Published by the AIP Publishing

The transport of samples under true UHV conditions from one instrument to another, sometimes from one institution to the other, is an increasingly important task in modern surface science. Ferrovac is constantly extending its product range in order to provide tailor made solutions. We would like to present our new models of NEG/Ion pumped UHV suitcases optimized in size, cost and performance.

The transport of samples under true UHV conditions from one instrument to another, sometimes from one institution to the other, is an increasingly important task in modern surface science. Ferrovac is constantly extending its product range in order to provide tailor made solutions. We would like to present our new models of NEG/Ion pumped UHV suitcases optimized in size, cost and performance.

M Sacchi et al 2013 J. Phys.: Conf. Ser. 425 202009

M Sacchi, H Popescu, R Gaudemer, N Jaouen, A Avila, R Delaunay, F Fortuna, U Maier and C Spezzani

We have designed, built and tested a new instrument for soft x-ray scattering experiments. IRMA-2 is a UHV set-up for elastic and coherent scattering experiments developed at the SEXTANTS beamline of the SOLEIL synchrotron. Applications will be in the field of solid state physics, with emphasis on the investigation of the magnetic properties of artificially structured materials.

Our currently largest of many sample receiver and storage solutions is the pictured RECOMSTAGE(D20).

Our currently largest of many sample receiver and storage solutions is the pictured RECOMSTAGE(D20).

CH Switzerland

CH Switzerland WORLDWIDE eCommerce only

WORLDWIDE eCommerce only GB United Kingdom &

GB United Kingdom &  IE Ireland

IE Ireland CN China

CN China JP Japan

JP Japan KR Korea, Republic of

KR Korea, Republic of SG Singapore &

SG Singapore &  MY Malaysia &

MY Malaysia &  ID Indonesia

ID Indonesia TW Taiwan

TW Taiwan US United States

US United States AU Australia &

AU Australia &  NZ New Zealand

NZ New Zealand SLAPXPS :: Solid-Liquid Ambient Pressure XPS Endstation with Analysis Chamber Module

SLAPXPS :: Solid-Liquid Ambient Pressure XPS Endstation with Analysis Chamber Module

The system (pictured above) consists of a customized

The system (pictured above) consists of a customized

June 2015

June 2015

Energy Collimator Specifications

Energy Collimator Specifications This simulation shows a support beam hanging freely without any base and with a 7kg load. In an overscaled representation, the displacement of the tip is calculated to be less than 0.05 mm.

This simulation shows a support beam hanging freely without any base and with a 7kg load. In an overscaled representation, the displacement of the tip is calculated to be less than 0.05 mm.

May 2015

May 2015

A magnetically coupled manipulator arm can grab the plug (right) out of a parking holder and safely transfer it linearly over half a meter distance under ultra high vacuum. In each of the 3 chambers a rotatable carousel (below) can hold up to 4 cathode plugs.

A magnetically coupled manipulator arm can grab the plug (right) out of a parking holder and safely transfer it linearly over half a meter distance under ultra high vacuum. In each of the 3 chambers a rotatable carousel (below) can hold up to 4 cathode plugs.

The figure to the right shows how the vacuum suitcase is connected to the gun loading chamber. The fine adjustment knob of the magnetically coupled manipulator keeps the cathode pushed into the gun during operation.

The figure to the right shows how the vacuum suitcase is connected to the gun loading chamber. The fine adjustment knob of the magnetically coupled manipulator keeps the cathode pushed into the gun during operation. The quantum efficiency of the cathodes depends on three theoretical parameters: the work function, the surface reflectivity and the local electric field (for a given laser wavelength). Contamination and roughness directly affect these parameters. The PPLS enables optimized preparation procedures and actions for the cathodes.

The quantum efficiency of the cathodes depends on three theoretical parameters: the work function, the surface reflectivity and the local electric field (for a given laser wavelength). Contamination and roughness directly affect these parameters. The PPLS enables optimized preparation procedures and actions for the cathodes.

April 2012 -

April 2012 -