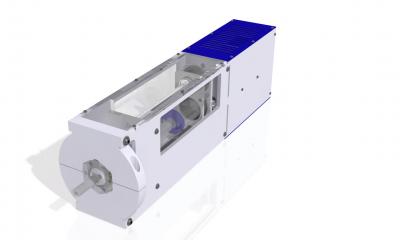

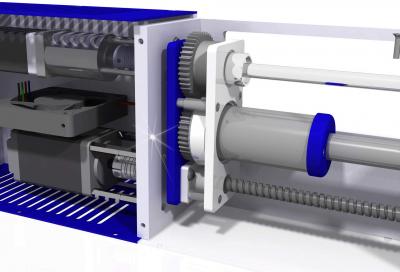

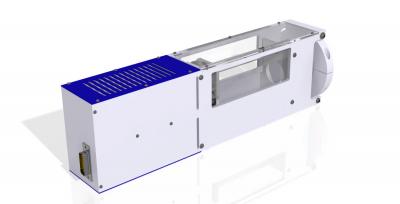

motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16, motorized, linear, rotary, drive, feedthrough, stepper, motor, spindle, phase, pitched spindle, DRVMDMOTLR16